No. 37 Production and evaluation of Insect repellent biodegradable films containing cyclodextrin

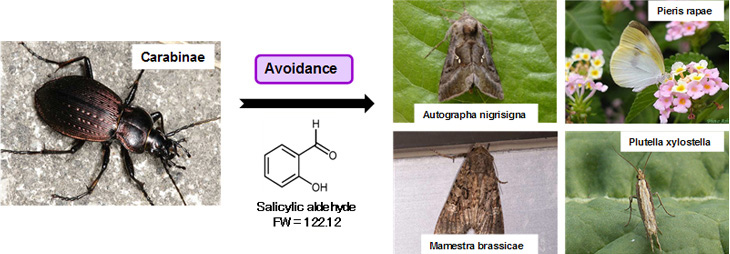

Salicylic aldehyde

Salicylic aldehyde (SA) is a substance released for self defense by such a insect as carabinae roam prey insect. Use minute amounts of SA has been found to exhibit a strong repellent effect on gene level for several lepidopteran. When applied as a pesticide in vegetable cultivation, it is safe for human and animals, and its environmental impact is low1).

SA is difficult to handle because it is liquid volatile and also chemically unstable, that is, easily oxidized or polymerized. And so we studied SA powderization by CD complexation so that we could improve handling easiness, enhance stability and add sustained release characteristics2).

1) Jun SHIMADA, Rejectant of lepidopteran、Patent Disclosure 2006-206519.

2) Mayu ONISHI, Hirokazu SHIGA, Yukiko UEKAJI, Daisuke NAKATA, Keiji TEREO, Jun SHIMADA Proceedings of the 27th Cyclodextrin symposium, p154-155, 2010.

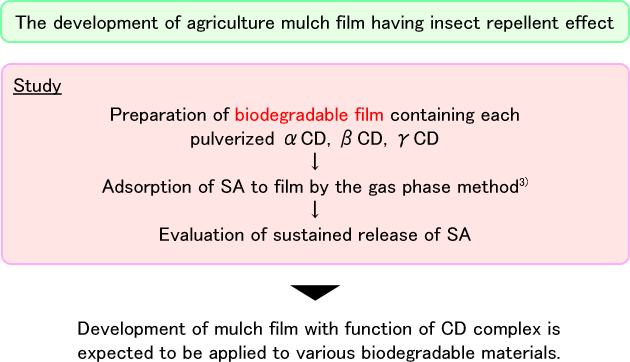

Content of study

3) B. MARTEL, M. MORCELLET, D. RUFFIN, F. VINET and M. WELTROWSKI, Capture and Controlled Release of Fragrances by CD Finished Textiles, Journal of Inclusion Phenomena and Macrocyclic Chemistry, 44: 439-442, 2002.

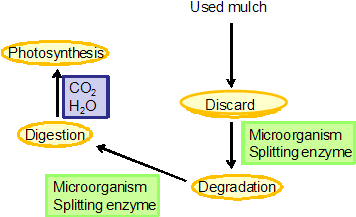

Biodegradable mulch film

Mulch film is used in agricultural field for water conservation, weed reduction, temperature control.

After use, Biodegradable mulch film, is decomposed into water and carbon dioxide by microorganisms, and returned to nature.

Advantages

Labor saving / Stable quality / Productivity improvement / Environmentally friendly / Waste eduction

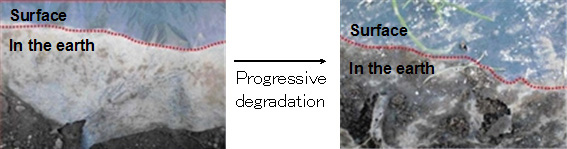

picture : MKV dream Ltd home source

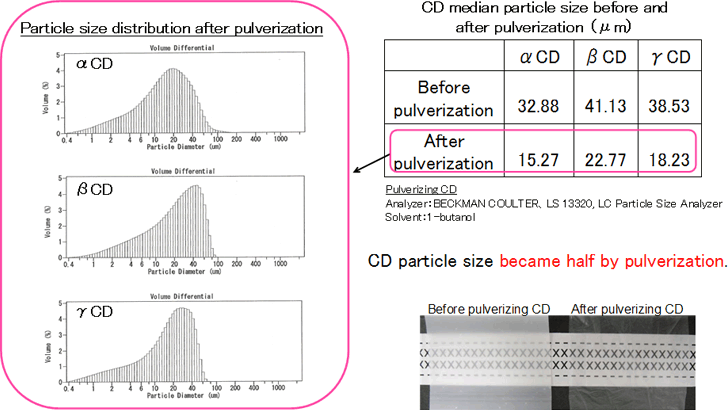

Particle size distribution of pulverized CDs

By using the pulverized CD, the formation of thin uniform film was confirmed.

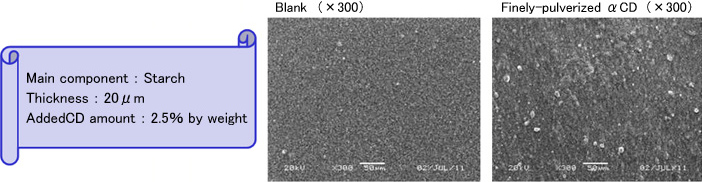

Electron micrograph of biodegradable film

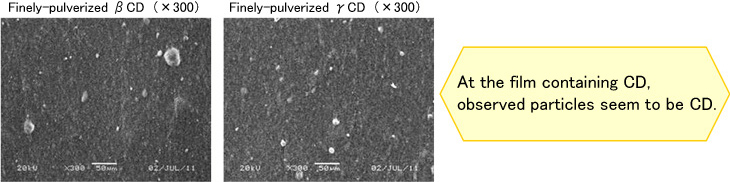

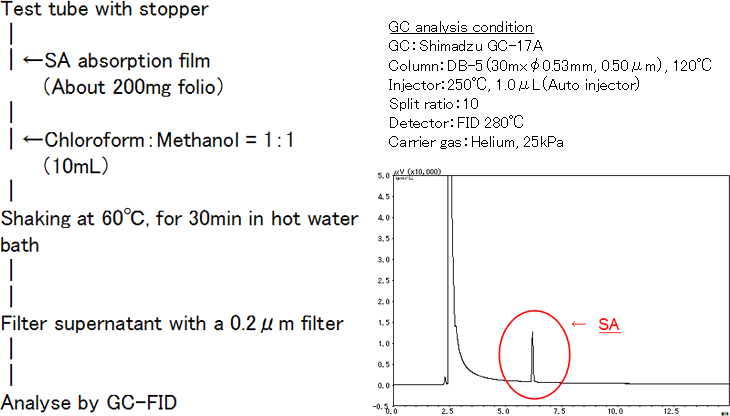

Adsorption method

Extraction method

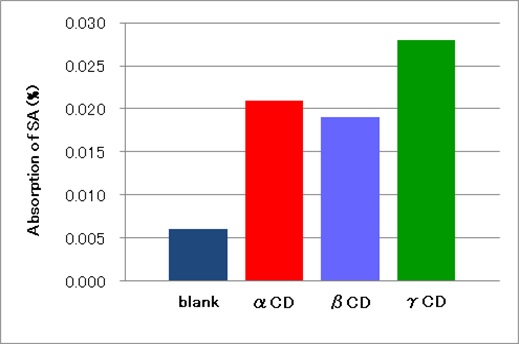

Absorption of SA for various CD films

SA adsorption amount per weight per day after air dry

Absorption of SA to the film

γ-CD film > α-CD film > β-CD film

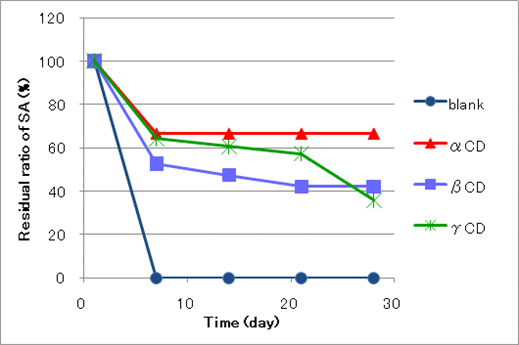

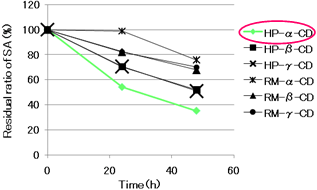

SA sustained release from various films

Residual rate of SA in the film (100% : Initial adsorption amount after air drying)

SA residual rate in the film after air drying for 28 days

α-CD film > β-CD film > γ-CD film

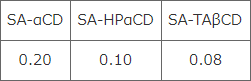

Insect protection advantage test of SA-CD film

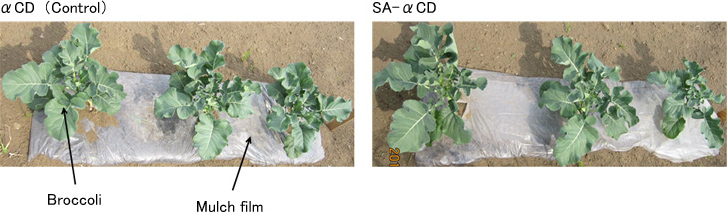

Insect protection advantage test in broccori grown with SA-CD biodegradable film

Film samples

- α-CD film (Control)

- SA-α-CD film

- SA-HPα-CD film

- SA-TAβ-CD film

Method

Four fields were coated with tour kinds of film (About 45 x 150cm)

|

There seedings of broccoli were planted for each film field

|

Larvae and pupae of insects were counted after 40 days

Field trial

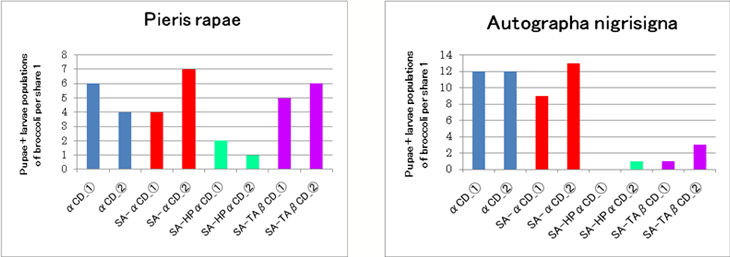

Insect protection advantage: conclusion of SA-CD film

Spawning inhibition for the Pieris rapae and Autographa nigrisigna was observed in the SA-HPα-CD film.

↓

HP-α-CD which was reported to release SA most quickly at the last year's CD symposium among various clathrate showed to posses the highest insect protection advantage.

Conclusion

- By atomizing the CD, a thin uniform thickness film was formed.

- It is suggested that SA is not merely adsorbed on the film material, but may be present on the film surface as CD clathrate.

- Adsorption capacity of SA was the highest at γ-CD film.

- The retention of SA was the highest at α-CD film, and sustained release of SA was observed for γ-CD film.

- Incect protecting advantage has been proven by the release of SA from the film.